Optimize dairy production with SS Engineers' Mini Dairy Plant, an advanced solution for organic milk processing directly at the farm. Farmers pasteurize and standardize milk fat on-site, using a batch pasteurizer and cream separator, and package fresh milk the same day to ensure quality. Milk is collected, filtered, and rapidly cooled to 4°C to minimize bacterial growth and retain freshness.

Process up to 3,000 liters daily, sourced on-site or from nearby farms. The plant offers flexibility to adjust fat content, with extracted cream convertible to butter, butter oil, or ghee, supporting diverse dairy product output.

We offer has designed three modules of milk processing for the farmers to choose from based on their milk production capacities.

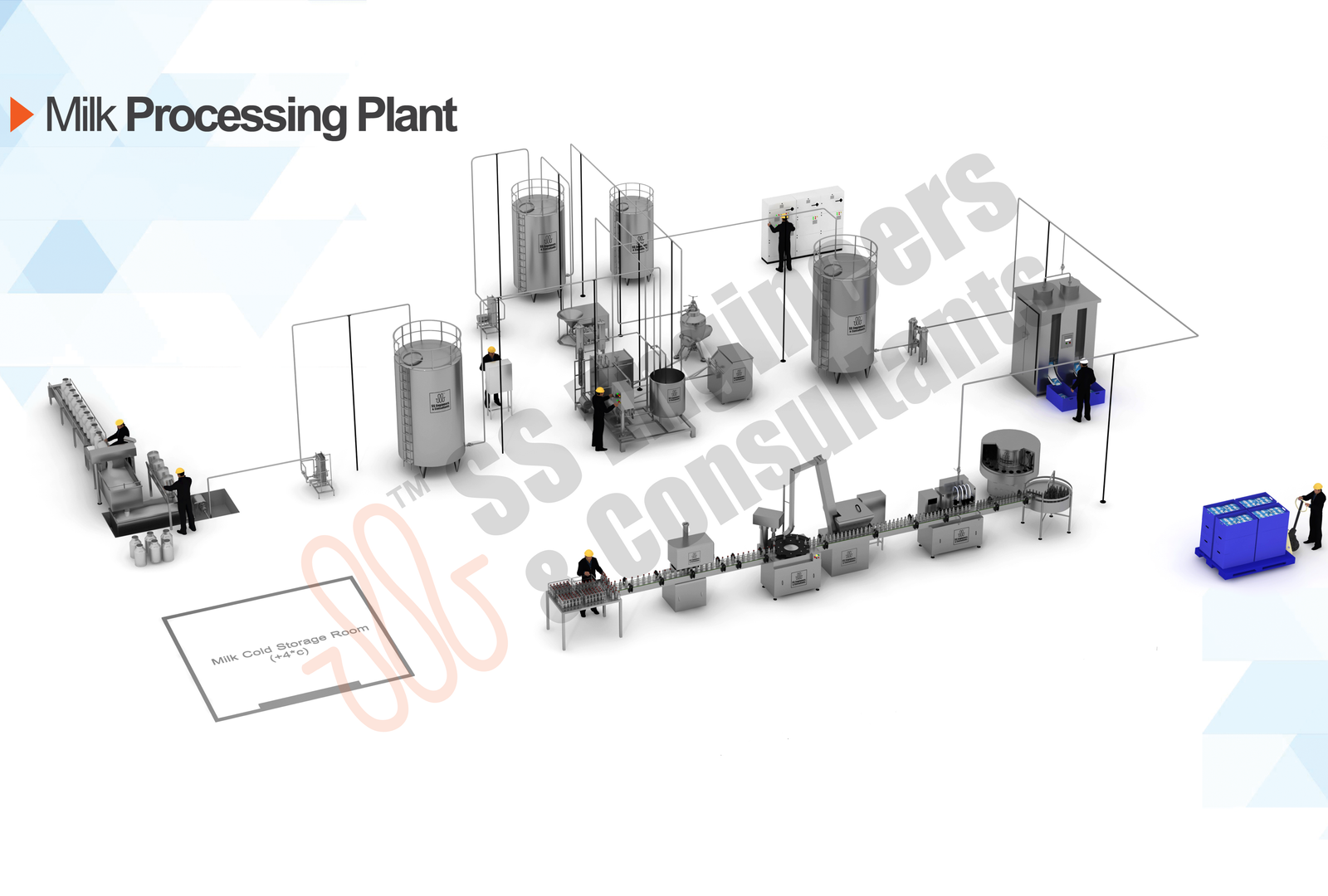

A milk processing plant is a facility where raw milk from dairy farms is processed into safe and consumable dairy products such as pasteurized milk, cream, yogurt, butter, and cheese. The plant ensures milk undergoes various treatments to meet food safety standards before it reaches consumers.

Milk processing involves several key steps: collection of raw milk, clarification and filtration to remove impurities, pasteurization to eliminate harmful bacteria, homogenization to ensure uniform consistency, cooling to preserve freshness, and finally packaging for distribution. Each step is designed to maintain quality and safety.

Pasteurization is a process that heats milk to a specific temperature (usually around 72°C or 161°F) for a short period to kill harmful microorganisms like bacteria and pathogens. It helps ensure milk is safe to drink while retaining its nutritional value. After pasteurization, milk is quickly cooled to prevent spoilage.

Homogenization is the process of breaking down fat molecules in milk into smaller, uniform particles. This prevents the cream from separating and rising to the top, resulting in a smoother, more consistent milk product. It enhances the texture and ensures that the fat is evenly distributed throughout the milk.

Milk quality is ensured through rigorous testing of raw milk for bacteria, antibiotics, and contaminants before processing begins. The plant follows strict guidelines for pasteurization, hygiene, and storage. Continuous monitoring and regular quality checks are performed at every stage to maintain safety and freshness.